Spotlight on Power Tools: Regulatory Developments Every Manufacturer Should Know

This blog was originally posted on 26th March, 2024. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

AUTHORED BY JOYCE COSTELLO, SENIOR REGULATORY COMPLIANCE SPECIALIST, COMPLIANCE & RISKS

Introduction

The market share of power tools has been steadily growing in recent years, and with it regulations ensuring these appliances meet high safety and efficiency standards. While power tools regulations are on the rise, this highly innovative sector has also seen an increase in dependence on batteries to power the growing cordless tool segment.

What follows below is a snapshot of just some of the many global rules impacting the operations of suppliers in the power tool industry today.

EU: Batteries Regulation (EU) 2023/1542

Conscious of the proliferation of battery technology and the escalating reliance of industry on them, regulators in the EU have introduced ever more stringent rules regarding, among others, the toxicity of batteries, facilitation of their removal from appliances by end-users, labeling and information requirements.

The power tool industry is set to be substantially affected by these new rules which apply, among others, to producers supplying batteries, including those incorporated in appliances, such as electrical and electronic tools.

Producers of power tools incorporating batteries need to comply with the general sustainability and safety requirements prescribed, along with labeling and information requirements.

What’s more, specific performance and durability requirements apply to portable batteries of general use, whether or not these are rechargeable. By 18 August 2027, the Commission will also have adopted minimum values for electrochemical performance and durability parameters, in order to reduce the life cycle environmental impact of batteries.

Regarding removability and replaceability of portable batteries, from 18 February 2027 companies placing products incorporating portable batteries on the EU market will be required by law to ensure that those batteries are readily removable and replaceable by the end-user at any time during the lifetime of the product. This should leave sufficient time for operators to adapt the design of their products to this requirement.

Of more immediate concern is the looming cut-off date of 18 August 2024, after which portable batteries, whether or not incorporated into appliances, cannot contain more than 0,01 % of lead.

Chile: SEC Certification for Circular Saws, Hand-held Drills and Impact Drills and Associated Battery Chargers

Effective 1 January 2024, Chile’s SEC is requiring safety certification of circular saws in accordance with IEC 62841-2-5:2014, as per Protocol PE No. 6/05:2022. Local legislation mandates that the month/year of manufacture of the product and/or serial number, or other means of traceability, must be marked on the product. Importers should also ensure that their products indicate the country of manufacture. As normal, appropriately-certified products should bear the Certification Marking (SEC Seal).

Also commencing 1 January 2024, hand-held drills and impact drills should be tested to IEC 62841-2-1:2021 in order to meet the requirements of PE No. 6/01:2022, and carry the stipulated markings, including the SEC Seal.

Batches of products certified under previous Protocols before 1 January 2024 may continue to be marketed while stocks last.

Again, power tool manufacturers need to be considering the batteries being supplied with their product ahead of the implementation of Protocol PE No. 1/40:2023 on 31 January 2025.

Products subject to PE No. 1/40:2023 include external battery chargers, whose batteries are charged either inside or outside hand tools, battery chargers, both when sold independently, as an accessory or spare part, or when sold together with hand tools. All battery chargers that are marketed without a specific purpose but that are also used to charge batteries for hand tools, lawn and garden machinery, are also included.

Products will only be allowed on the market in Chile if they can show certification has been obtained in accordance with the scope and field of application of IEC 60335-2-29:2019 and CEI 23-50/CEI EN 50075 (CEI 23-34). Traceability and SEC marking applies as normal.

China: Mandatory Energy Labeling for Welding Machines for Industrial Use

Welding machines for professional use must carry an energy efficiency label from 1 June 2024. China’s Energy Label (CEL) 043 applies to arc welding machines and resistance welding machines for industrial and professional service purposes.

The minimum allowable values of energy efficiency and energy efficiency grades for welding machines to be followed are defined in Standard GB 28736-2019.

A two-year transition period will be allowed for welding machines manufactured or imported before 1 June 2024, after which such machines must bear an energy label.

Japan: Foreign Manufacturers Selling Power Tools Directly to Consumers to Appoint Responsible Person in Japan

Japan’s METI is introducing legislation to ensure that foreign businesses selling products directly to domestic consumers in Japan, usually via online sales, have a responsible person in Japan who may be held liable for failure to meet obligations under the national Product Safety Acts, including DENAN, the electrical appliance safety act.

Overseas operators selling products directly to general consumers in Japan without going through manufacturers and importers will therefore need to designate a responsible person ahead of the proposed implementation date for this new requirement, December 2025.

UK: Extension to Flexible Approach to Product Marking

The announcement by the Department of Trade in the UK that the current flexible product labeling requirements will be made permanent will benefit power tools manufacturers, among others, supplying their products both in the EU and in the UK.

With regard to the continued CE recognition, in practice this will mean the continued recognition of the CE mark and declaration of conformity based on 21 product regulations, and cover most products coming within the EU’s harmonized regime.

The same declaration of conformity used to market goods in accordance with EU regulatory requirements will therefore also be accepted in the UK, provided that it is translated into English, lists the regulations met and indicates how these have been met.

The proposed legislation to officially allow the extended recognition of CE marking is anticipated to be laid before Parliament this Spring, and will come into effect later this year.

Businesses who wish to assess products in accordance with UK requirements and use the UKCA label can continue to do so, as this remains a valid and robust approach to product conformity. The Government is developing a fast-track UKCA optional process for products placed on the market in England, Wales and Scotland, which will enable manufacturers to use the UKCA mark based on tests completed to either UK or EU requirements.

The new option for digital labeling is also still firmly on the agenda, with legislation expected later in the year on this new option, which will however be applicable to UKCA only.

Stay on Top of Power Tools Regulations

Want to stay ahead of evolving regulatory developments and power tools regulations?

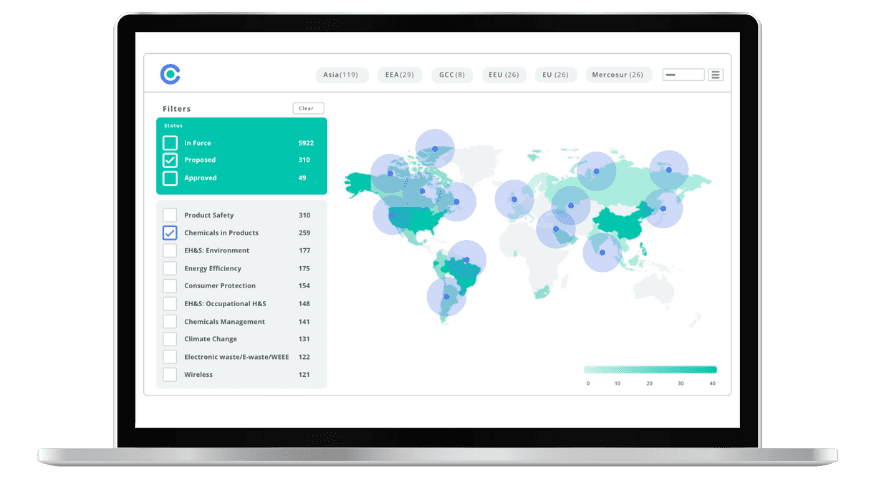

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – Your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Reducing Manual Efforts In Regulatory Impact Assessment

Join us for an insightful webinar where we’ll explore strategies, tools, and best practices for reducing manual efforts in Regulatory Impact Assessment.