Labeling that Lasts: Durability of Labels for Lead-Acid Batteries

This blog was originally posted on 14th April, 2025. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

AUTHORED BY ANDREW O’NEILL, REGULATORY COMPLIANCE SPECIALIST, COMPLIANCE & RISKS

Background

Lead-acid batteries power everything from cars to telecom backup systems, and their labels carry critical safety and recycling information. But it’s not enough for a battery label to simply exist; it must endure the harsh conditions of real-world use. Around the world, regulators and standards bodies have set requirements to ensure these labels remain legible and intact despite exposure to acid, heat, sunlight, abrasion, and more. This blog explores the durability requirements and standards for lead-acid battery labels across Europe, Asia, the Americas, Africa, and Australia. Topics include regulatory bodies, definitions of durability (chemical, UV, abrasion, temperature resistance), relevant standards, environmental considerations, and enforcement mechanisms.

Europe: Indelible Markings and Harmonized Standards

European regulations mandate that labels on lead-acid batteries be visible, legible, and indelible. The EU Batteries Regulation (EU) 2023/1542, replacing the older Battery Directive 2006/66/EC, outlines labeling content and durability expectations. Labels must withstand acid, oil, abrasion, heat, and UV light. Markings like the crossed-out bin symbol and the chemical symbol “Pb” must be permanent. Common standards referenced include IEC 62902:2019, which defines durability tests using water, battery acid, and cleaning solutions. Product-specific standards like EN 50342 for starter batteries require engraved or printed markings that cannot be easily removed. Environmental diversity in Europe pushes manufacturers to use materials such as UV-resistant ink on heat-resistant polymers. Testing is typically part of CE conformity assessments and may include rubbing, immersion, and accelerated aging. National market surveillance ensures compliance.

Asia: Diverse Regulations with International Benchmarks

Asia features a diverse landscape, with countries like Japan, China, and India developing labeling regulations in line with international norms. Japan emphasizes durable materials and color-coded hazard labeling. China requires acid-resistant labels for lead-acid batteries and has adopted symbols like the crossed-out bin. India’s Battery Waste Management Rules mandate label permanence and size specifications, referencing ISO 28219 for print durability. Countries like South Korea and Taiwan follow the UN GHS framework, and many Southeast Asian countries default to international labeling norms due to imports. Testing standards are aligned with IEC and ISO protocols, and enforcement ranges from industry self-regulation to active market inspections by environmental agencies.

The Americas: Safety Standards and Patchwork Regulations

In North America, durable battery labeling is addressed through industry standards like UL 969 and CSA C22.2 No. 0.15, which set rigorous durability tests involving chemical exposure, UV, and abrasion. The U.S. Battery Act and OSHA guidelines imply permanence through labeling mandates. Canada enforces similar standards under national and provincial regulations. In Latin America, countries like Brazil, Mexico, and Chile enforce recycling and hazard labeling rules, often referencing EU or U.S. practices. Durability is described using terms like “indelible” or “permanent,” and environmental diversity drives the use of weatherproof and acid-resistant labels. Testing may include tropical climate simulations, and enforcement varies, but generally follows environmental compliance and market checks.

Africa: Emerging Standards and Reliance on Global Norms

African nations increasingly incorporate label durability into battery regulations, though formal standards are still developing. South Africa mandates environmental labeling under Extended Producer Responsibility (EPR) laws, requiring weather-resistant, legible labels. Other countries like Kenya and Nigeria use EU-style language, calling for “indelible” and “permanent” labeling. Most batteries are imported and already comply with international standards. ISO and IEC references guide national drafting. Africa’s diverse climate necessitates labels that resist humidity, UV, and dust. While formal testing infrastructure is limited, enforcement may occur through inspections and NGO-driven programs encouraging public awareness of proper labeling.

Australia: Embracing Global Best Practices Down Under

Australia and New Zealand follow international best practices, integrating standards like ISO 3864-2 and AS/NZS 60079. Regulatory bodies include the ACCC, Standards Australia, and the Department of the Environment. Label durability is not always legislated directly for lead-acid batteries but is enforced through general product safety laws. Labels must resist UV, heat, and chemicals due to Australia’s harsh climate. Industry standards recommend embossed or laminated labels, and testing mimics IEC rub and weathering protocols. Australia’s Battery Stewardship Scheme promotes long-lasting recycling labels. Enforcement primarily occurs through consumer protection laws and voluntary industry compliance.

Summary of Key Label Durability Requirements

| Europe | Asia | Americas | Africa | Australia | |

| Key Durability Requirements | Indelible, legible under acid, UV, oil, heat, abrasion | Acid-resistant, UV-stable, GHS symbols, size specs | Weatherproof, permanent, abrasion/chemical resistant | “Indelible”, “permanent” labels; mostly imported goods | UV/heat/chemical-resistant, industry-driven, laminated or embossed |

| Common Regulations & Standards Referenced | EU 2023/1542, EN 50342, IEC 62902 | ISO 28219, IEC standards | UL 969, CSA C22.2 No.015 | ISO/IEC references, local EPR frameworks | AS/NZS 60079, ISO 3864-2 |

| Enforcement Mechanism | CE assessments, national market surveillance | Mix of self-certification, audits, environmental checks | OSHA, EPA, provincial agencies, consumer product reviews | Spot inspections, NGO programs | ACCC enforcement, voluntary schemes like Battery Stewardship |

Global Trends and Summary

Label durability for lead-acid batteries has become a global regulatory focus. Across all regions, labels must resist chemical exposure, UV radiation, abrasion, and temperature extremes. Symbols such as the crossed-out bin and “Pb” for lead are universally expected to be permanent. International standards like IEC 62902, ISO 28219, and UL 969 serve as common benchmarks. Regional differences exist, but harmonization is increasing, driven by safety, environmental responsibility, and market expectations. Testing protocols include chemical resistance, UV weathering, rub tests, and thermal cycling. Enforcement is carried out through conformity assessments, market surveillance, and industry self-regulation. As batteries evolve, durable physical labels remain essential to convey safety and recycling information reliably throughout the battery’s life.

Stay Ahead Of Regulatory Changes

Want to stay ahead of these regulatory developments?

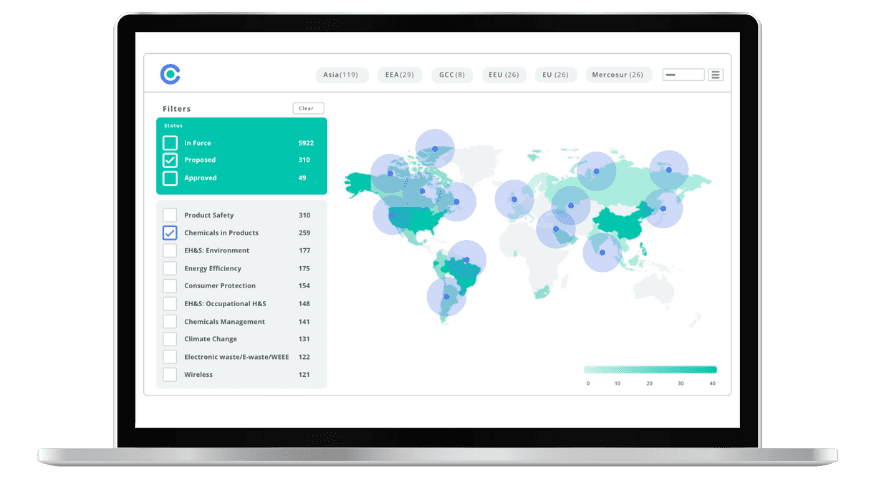

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Chemical’s Quarterly – Q1 2025 Regulatory Update

Get an overview of the latest news on permitted, restricted and prohibited substances in a variety of products from around the world.